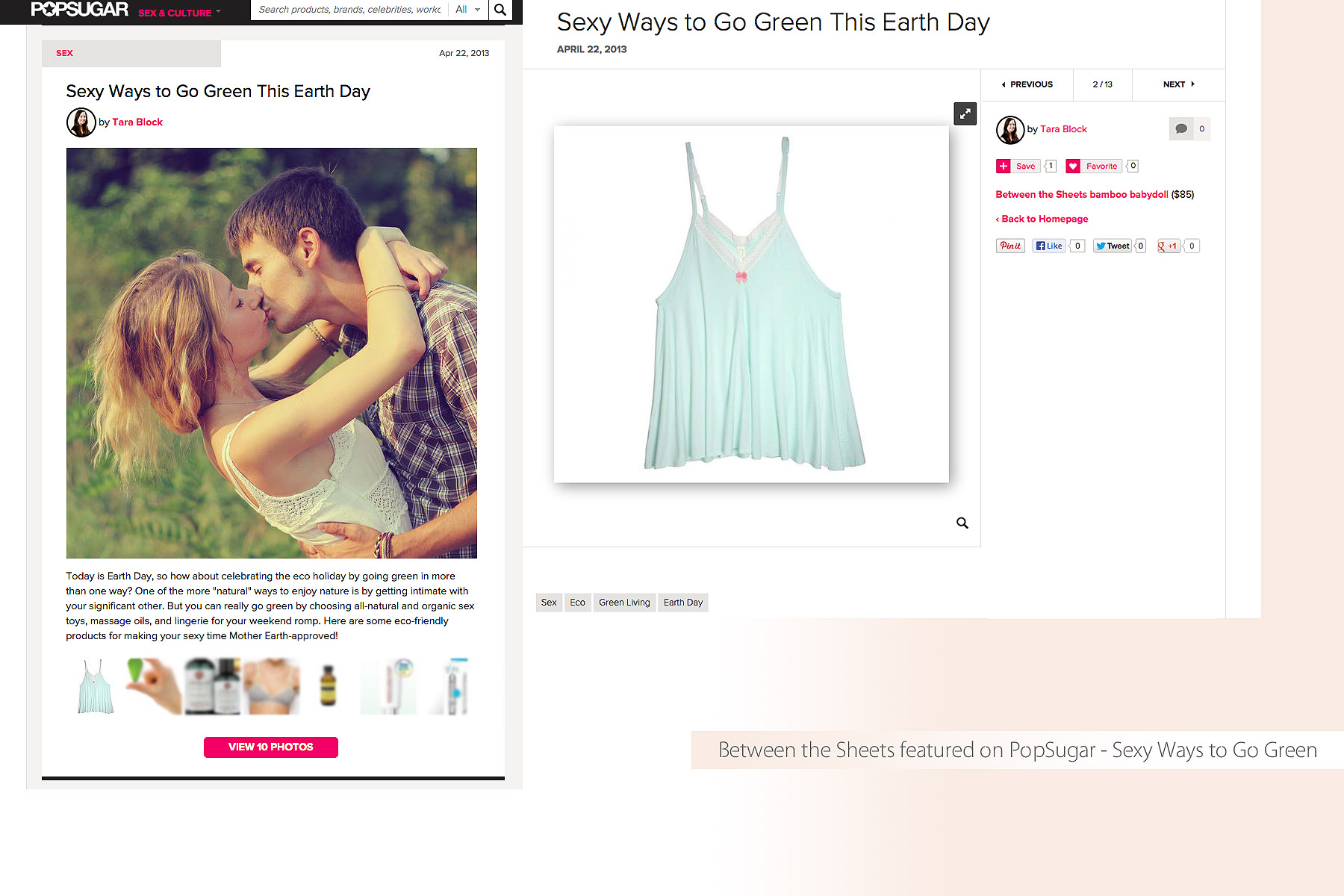

Popsugar gets green in this sexy Earth Day gift guide featuring our new Come Out and Play babydoll, made of sustainable micro-modal with Made in USA lace trim and manufactured right here in NYC it’ll cut your top drawer’s ecological footprint down to “earth hugger”.

Press: Ecouterre Vday 2013 Eco-friendly Lingerie Gift Guide

Our Arabesque set in Ruby red made top of the fold in this eco-friendly lingerie gift guide by Ecouterre for Valentine’s Day 2013, making this little indie label proud. Many of you know we make a huge effort to remain transparent and ethical in our manufacturing by remaining Made in the USA, and its wonderful to be featured alongside other brands making similar efforts!

behind the scenes – between the sheets factory life

We’ve been so behind on blogging because we’ve been busy getting ready for our most intense season of production yet! Fall and holiday are always big for sleepwear and loungewear, and that being our signature means we’re kicking it into overdrive. Not to mention an exciting new collection we start production on next month to launch early in the New Year – get a sneak peek on our brand site: betweenthesheetscollection.com

So while we were away from our computers we’ve been tweeting and instagramming – follow us @BTSlingerie here online if you don’t have an account! We thought we’d bring you a peek at what we’ve been up to here on the blog.

Care labels arrive: we make sure sewers can understand which care label goes on which garment using the international language of doodling.

Fabric arrives: How to cut through all of that tape… when its all open its laid out to cut and then off to the sewing line.

As pieces come off the line we check that each color/size is “in spec” meaning they don’t run too small or too large.

We make sure each piece got the right care label – Yes! Our doodling has paid off! Then we add a hangtag to each piece.

For those of you who do not have the pleasure of owning one of our pieces here’s a snap of our hangtag. Back when we were making behind the scenes of BTS fashion show our video editor Vinnie came up with this little bit of genius – the definition of lingerie and Between the Sheets. Thanks Vinnie!

We inventory to make sure we got the correct number of pieces and check for any defects in stitching, coloring, or fabric. Then we pack each piece individually.

There is a lot of packing… and no robots here this is all done by hand!

We get distracted by the cute kitten who is our new factory mascot… Could you refuse that face?

We drink copious amounts of coffee on a daily basis. Our livers seem ok with it so far…

Back at the studio we’re working on the next season, perfecting patterns. And for those of you who think a career in fashion means no math… we hope you didn’t skip that class on fractions.

We gather lots of bits and bobs for sample making.

We cut out fabric for samples… and these styles you’ll have to wait for next season to see!

And again we find ourselves disctracted by furry creatures… we’re not complaining.

You can already shop the Petal Play lace styles seen in this post! Click the picture below to shop!

- « Previous Page

- 1

- 2

- 3

- 4

- 5

- 6

- …

- 9

- Next Page »